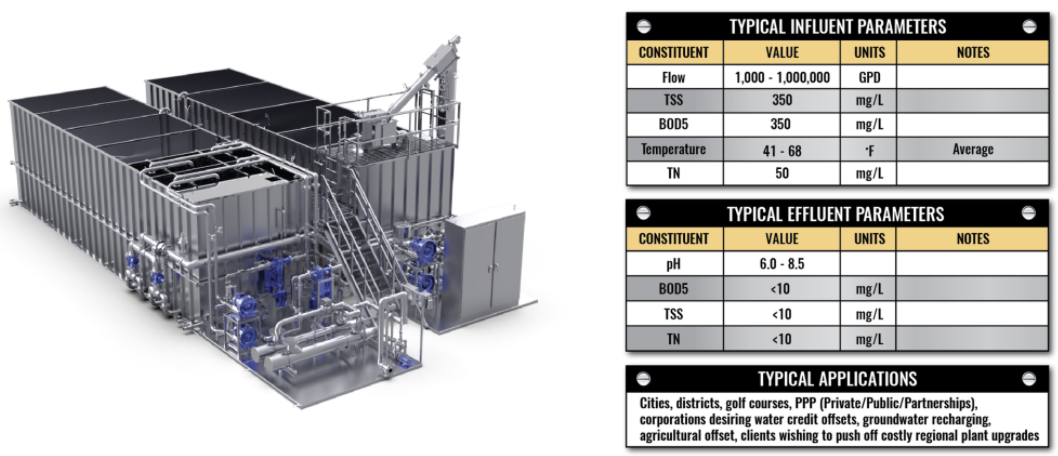

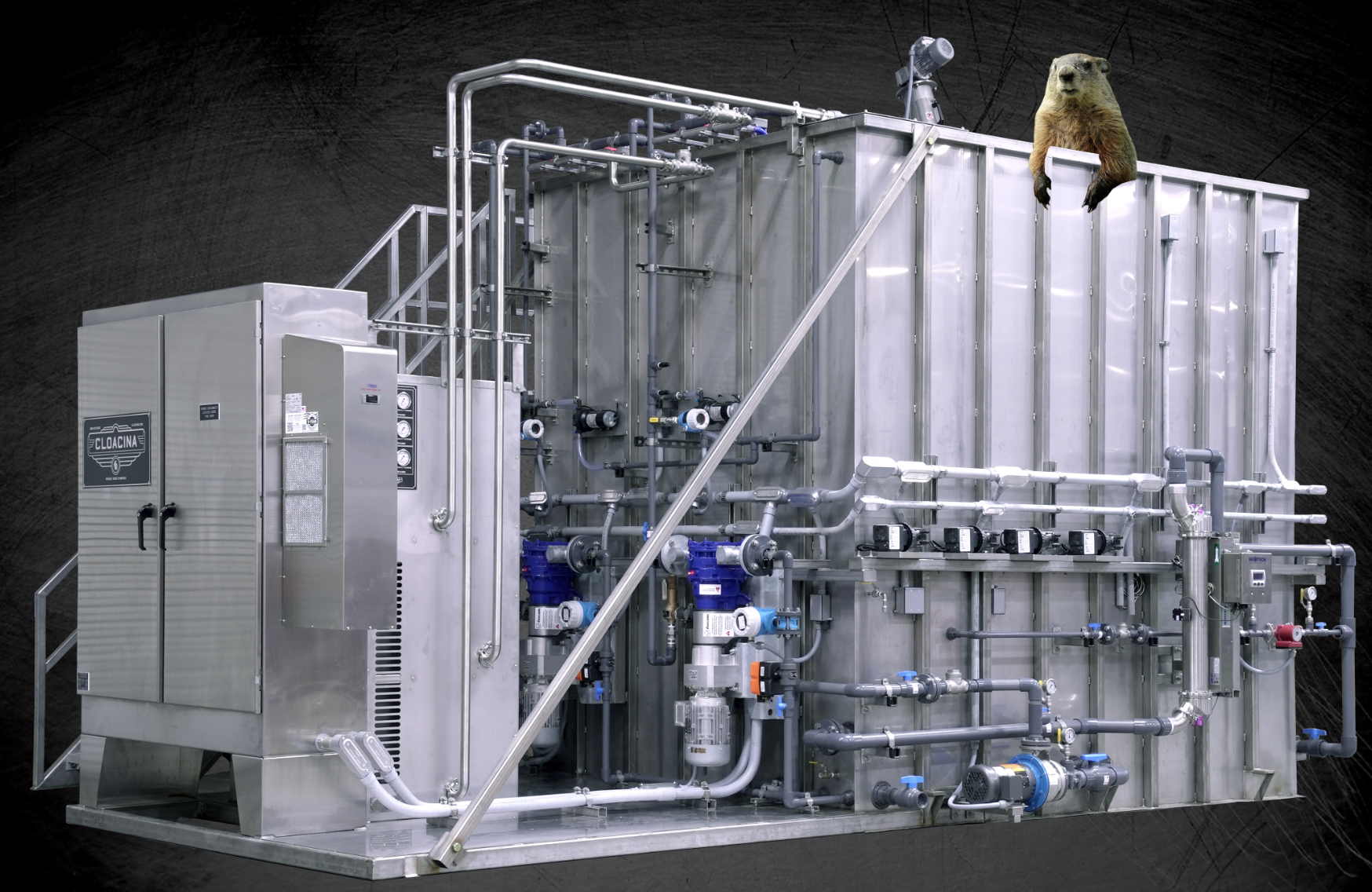

Cloacina’s MEMPAC-S (Scalping) is one of the most revolutionary products currently available in wastewater treatment. Untreated domestic wastewater is intercepted, pumped out of the gravity sewer into the MEMPAC-S, treated to reuse standards and then discharged to irrigate parks and common areas, used to offset agricultural, irrigation or commercial water usage or recharge groundwater supplies using direct injection. Untreated solids are returned to the sewer. A scalping plant is an alternative to centralized wastewater treatment that can provide secondary or tertiary treatment within a smaller facility.

In times of drought and mandatory water conservation measures, it is no longer responsible to irrigate sports complexes, flowerbeds and medians with potable water, nor is it tenable to continue to send a valuable resource to final discharge locations such as the ocean when communities are struggling to maintain groundwater balance. Fabricated from stainless steel, the MEMPAC-S can reclaim 100% of the treated effluent in accordance with Title 22 requirements or any other state or national regulations, lessening the strain on diminishing potable water and groundwater supplies. By performing treatment adjacent to the disposal location, a scalping plant is an affordable reuse option.

OPTIONAL FEATURES

Extended warranty

pH adjustment system

Denitrification/BNR

Package lift station

Prefabricated controls building

Sludge disposal equipment

Incorporation of existing controls equipment into Cloacina’s controls package

Energy saving controls package upgrades

Effluent flow metering

Additional equipment sound attenuation

Automated Clean In Place (CIP) system

Disinfection system

Thermal protection

Mobile units

Odor mitigation equipment

Automated foam control

Sediment/grit traps

Variety of grating and covers available

Project management

Equipment installation

Operations and maintenance training and services

Remote monitoring and support

STANDARD FEATURES

304 stainless steel tankage

Controls system

Influent screening

Membrane cassettes

Semi-sound attenuated, positive displacement blowers

Modular medium bubble diffusers

All sensory equipment and internal pumps are mounted on Cloacina’s Slide Rail System

Above-ground installation

Human Machine Interface (HMI)