Cloacina is revolutionizing the package wastewater treatment industry! Clients notice a tangible difference in every phase of the project when they work with Cloacina -- this is what we call THE CLOACINA DIFFERENCE.

During the bidding and proposal phase:

Cloacina is contacted by a Client with needs ranging from the replacement of aging infrastructure to the desire to reclaim treated wastewater

Information about the project is collected and a job walk is conducted, if applicable

Clients and their project teams are invited to tour our factory as well as other installed Cloacina plants in operation similar to the one they are considering purchasing

A proposal is produced

Prospective Clients experience the Cloacina difference during their initial contact with our Sales Team and throughout the bidding and proposal phase. Here are some of the things that set Cloacina apart from our competitors at the beginning of a project:

Cloacina wants to be a member of the Client’s project team not just an equipment supplier. Our Sales Team works alongside the Client, their engineer and contractor to provide treatment options and design input.

Our Sales Team is prompt and responsive. They meet deadlines for information and proposals.

Cloacina is an open equipment integrator. We are flexible in our scope of supply if there is a piece of ancillary equipment the Client wants to be included in their new system.

We don’t want Clients to spend money on things they don’t need. If a piece of equipment or process is not necessary, it is eliminated.

We want Clients to know exactly what they are buying and how much it will cost. Our proposals are transparent and project-specific based on the Design Specifications. Cloacina’s proposals include value engineering, all costs to manufacture a complete treatment system and controls and electrical integration.

Cloacina encourages Clients and potential Clients to attend a virtual or in-person tour of one of our wastewater treatment plants. To schedule a tour, contact sales@cloacina.com.

Once Cloacina receives an executed contract from the Client, the project enters the Design Phase. Our Design Team, which consists of highly-skilled engineers and draftsmen, produces detailed, project-specific documents that include: process flow diagrams, process and instrumentation diagrams, biological modeling and structural analysis.

Unique aspects of Cloacina’s Design Phase include:

We do not believe in a cookie-cutter approach to wastewater treatment

Our Design Team members have decades of experience in designing package wastewater treatment plants

Every Cloacina package wastewater treatment plant and piece of equipment is designed and engineered to meet the Client’s specific discharge permit and waste stream

Our products can be integrated into existing on-site equipment and controls systems

The Design Team can provide Clients with calculations showing why each piece of ancillary equipment was selected for their particular project

We offer expedited design and engineering services on most models

Cloacina can provide Clients with equipment life cycle analysis

Our Design Team is highly responsive to Client questions and concerns throughout this phase

All Cloacina tanks and equipment skids are fabricated in-house from stainless steel as a standard. As a result, Cloacina has become one of America’s leading manufacturers of rectangular stainless steel tanks. This is part of the Cloacina Difference!

Since we only fabricate stainless steel products, there is no chance of cross-contamination with other metals

Our Fabrication Team consists of certified welders and stainless steel specialists

Our structural engineer is licensed in 48 states

Everything built in our factory must pass our rigorous quality control/quality assurance tests

Our tanks are chemically and electrochemically passivated and leak tested

Every product that leaves our factory is built by American hands!

Cloacina’s intuitive and user-friendly controls system features a graphical representation of the entire treatment process including tank levels and pump and motor activity. This revolutionary system comes standard on all Cloacina plants and many of our major pieces of equipment. Clients can access their controls system and make immediate operational changes to their plant from any device with an Internet connection. The controls system also allows alarm notifications to be texted, emailed or called in to multiple members of a facility’s staff to ensure prompt response to emergency conditions.

Some of the features of our controls system are:

All equipment and processes can be incorporated

Industrial-grade touch screen monitors are included

Clients can establish custom set points

The system can generate daily, weekly and monthly reports as well as maintenance due dates based on elapsed run times

Clients can receive daily event and alarm condition reports

Graphs can be customized to show only desired parameters

The system allows for varying levels of user access

There are no recurring license fees

The Cloacina controls system circuitry is protected by properly sized breakers and fuses and can be wired for any site voltage.

It has magnetic starters and switches and Variable Frequency Drives (VFD) control all electro-mechanical components.

One of the most revolutionary things about Cloacina’s package wastewater treatment plants is that they are factory assembled, filled to operating depth and rigorously tested as a complete system before shipping.

During factory acceptance testing each plant undergoes the following:

Tankage is cleaned and leak tested

All welds on the tankage are brushed and free of spatter and slag

All welds are cleaned and passivated through an electrochemical passivation process

Equipment is bump tested for functionality

Flow testing for pump rotation and leaks

All equipment is electrically tested and the results are recorded

Sensors are tested and configured

The controls system is tested in both manual and automatic modes

The controls system alarms, trending, notifications and setpoints are verified and recorded

All manual processes are performed and adjusted for easy operation

Equipment serial numbers are recorded

All factory setpoints are recorded

The system is cleaned and prepared for shipping

Every Cloacina package wastewater treatment plant under 150,000 GPD is factory-assembled and undergoes pre-commissioning as a complete system prior to shipping

Following factory acceptance testing, Cloacina plants are cleaned and prepared for shipping.

Cloacina’s packing and shipping process includes:

All tanks are drained, passivated and cleaned inside and out

Any pieces of equipment or piping that have to be removed for shipping are match marked for easy reassembly and then carefully wrapped and packaged

The Upfit Team verifies that all equipment is properly secured to the tanks and skids. Every bolt and clip is double checked.

The shipping company loads the tanks using the built-in rigging points. All tanks and equipment are properly secured before the shipper leaves the factory.

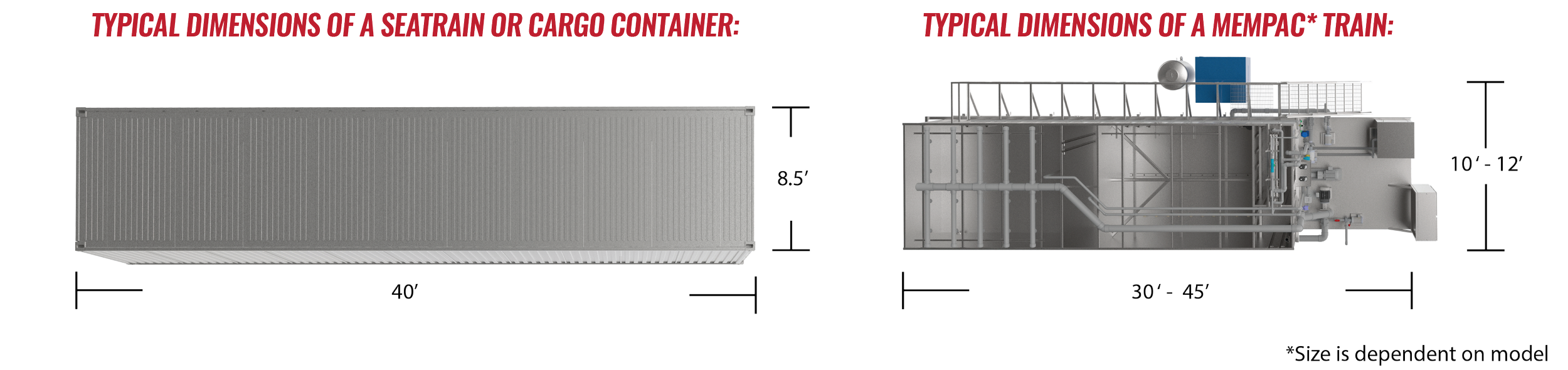

MEMPAC trains are similar to the size of a seatrain or cargo container and can be easily transported by barge, cargo plane, rail or lowboy trailer. Nationwide shipping is available.

Cloacina package wastewater treatment plants are designed to be easily installed. Our Project Managers work carefully with the Client’s contractor to ensure successful installations.

Cloacina provides every installation contractor with:

The opportunity to come to our factory to see the plant they are going to install during factory acceptance testing

An installation checklist specific to every project

Detailed tie in lists for utility locations

Match marked labels on all parts that are removed for shipping. This ensures that all parts are reassembled correctly regardless of the contractor’s experience with wastewater treatment systems.

Cloacina wastewater treatment plants are shipped and arrive at the site as complete systems, NOT individual pieces of equipment that need to be integrated. As a result, Cloacina systems can be installed up to three times faster than other wastewater systems.

Steps to install a Cloacina package wastewater treatment plant typically include:

Every Cloacina package wastewater treatment plant is factory-assembled and undergoes pre-commissioning as a complete system prior to shipping. As a result, start-up and commissioning of a Cloacina plant is expected to be a smooth, cost-effective process compared with other systems that are assembled and run for the first time on-site.

During plant start-up and commissioning, Cloacina provides:

Detailed start-up checklists

Inspection and pressure tests of all connection points

Verification that electrical connections and supply power meet project documents

Verification that each motor is rotating in the correct direction. Baseline performance values are recorded during real operating conditions.

Confirmation that all instrumentation is configured appropriately and per project documents

Review of seed sludge (Adding organisms in the aeration basin)

Comprehensive training of the operations staff

An Owner’s Information Packet which includes all project documents, warranty compliance, sampling schedules and other plant requirements

Cloacina Project Managers work closely with installation contractors and the operations staff to ensure a successful plant commissioning.