TYPICAL APPLICATIONS

Sanitary sewer pre-treatment, primary treatment prior to ponds or secondary treatment and Dissolved Air Flotation (DAF) effluent

PRODUCT OVERVIEW

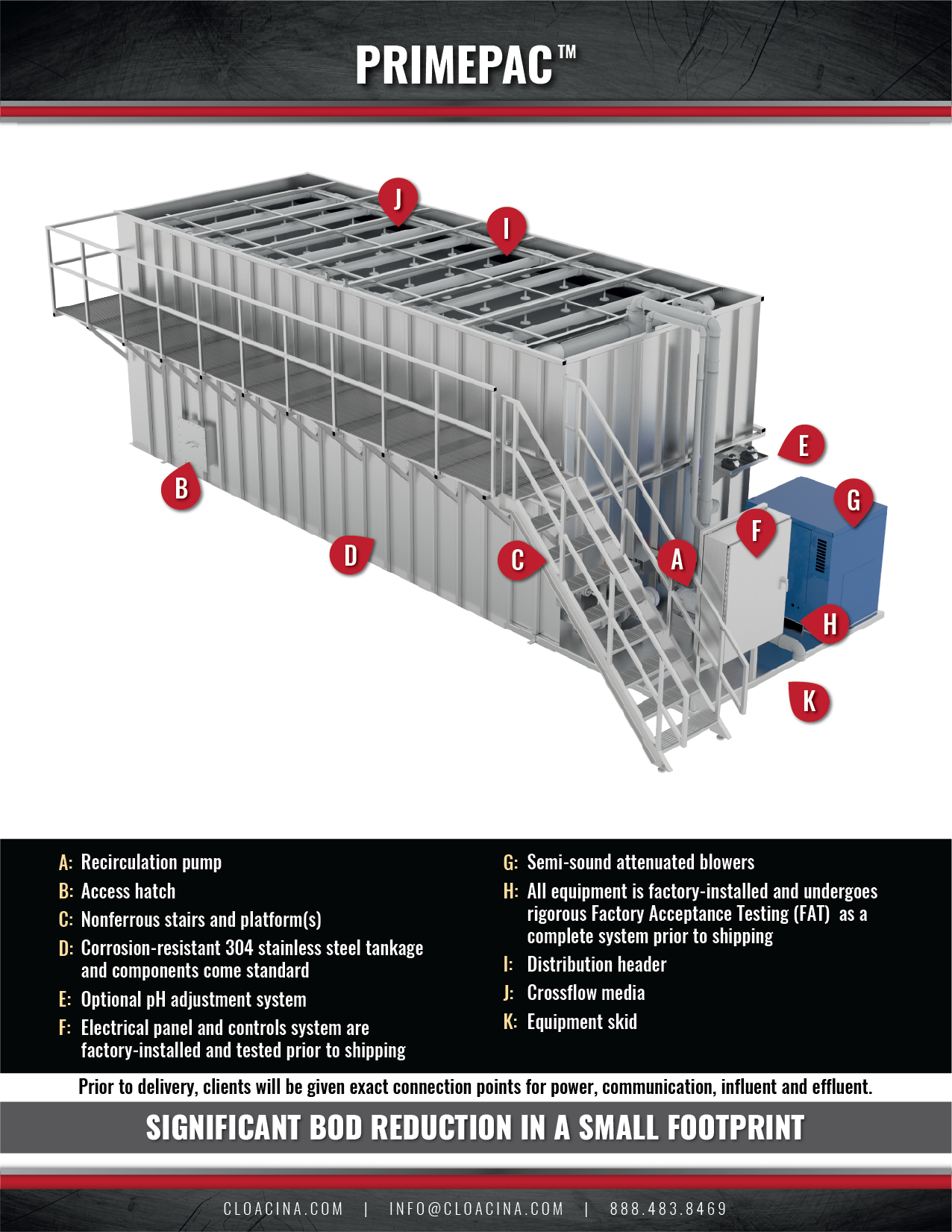

The PRIMEPAC™ package wastewater treatment plant utilizes the attached growth treatment process to reduce Biochemical Oxygen Demand (BOD) an average of 70%. This system is designed to treat process wastewater in an energy-efficient manner by utilizing fixed film growth and growing naturally occurring anaerobic and aerobic bacteria on the same media.

Cloacina’s PRIMEPAC is designed for clients who want to significantly reduce BOD and balance pH for pre-treatment, reduce sewer surcharge fees or increase the capacity of an existing pond or treatment system without the capital expenditures or operating expenses associated with advanced treatment.

This system requires the least amount of operational oversight of any of Cloacina’s wastewater treatment plants. It is easy to install, operate and maintain and, in many cases, can be installed without a slab with an optional earth anchor kit. The PRIMEPAC comes standard with stainless steel tankage, equipment skids and stairs, aluminum catwalks and non-ferrous piping. Every PRIMEPAC undergoes rigorous Factory Acceptance Testing (FAT), including wet testing, which significantly expedites plant start-up and commissioning. The system is factory-assembled and operational upon delivery. The PRIMEPAC can be easily expanded at a future date and is capable of reclaiming 100% of the treated effluent with the incorporation of Cloacina’s MEMPAC membrane bioreactor.

OPERATIONS AND MAINTENANCE-FRIENDLY FEATURES

Cloacina's package wastewater treatment plants are designed by operators for operators. Our Ownership Team has been building, installing, operating and maintaining water and wastewater systems for almost three decades. As a result, we know what operators and maintenance technicians need. Some of the revolutionary operations and maintenance-friendly features of our package wastewater treatment plants include:

Submerged sensory equipment is mounted on Cloacina’s Slide Rail System which provides mounting and support of equipment requiring precise installation and repeated removal for calibration and maintenance. This allows multiple pieces of equipment to be installed in tight spaces without tension on or tangling of power cords and controls cables.

The MEMPAC-M has built-in foam migration to keep foam and scum moving through the system and into a trap at the end of the treatment train

All process tankage on the MEMPAC-M has isolation gates for maintenance and emergency purposes

Equipment has pressure gauges or transducers for troubleshooting

All equipment has unions and/or flanged fittings for easy access and maintenance

All equipment is visible and easily accessed, maintained and replaced

We offer more sensory equipment and monitoring points on our systems than any other manufacturer

All models include self-cleaning probes

Our controls program provides:

Graphing

Trending

Charting

History

We provide built-in logic for oxygen control, nitrogen reduction and sludge management

STANDARD FEATURES

304 stainless steel tankage, equipment skids and stairs

Aluminum catwalks

pH adjustment system

Semi-sound attenuated blowers

Under drain access hatch

Aeration diffuser grid

Integrated controls panel

Effluent dump valve

Concrete slab installation

OPTIONAL FEATURES

Redundant equipment including: pumps, blowers, sensory equipment and PLCs

Sound-attenuated blower

Double stacked media for footprint reduction

Installation on compacted road base with earth anchors

Effluent disposal pump

Effluent TSS screen

Seismic anchor package for slab installation

VIDEOS

ABOUT CLOACINA