Overview

Cloacina’s DRYPAC Aerated Sludge Handling System is engineered to process Waste Activated Sludge (WAS) from various wastewater treatment configurations, including sequencing batch reactors, extended aeration, solids contact clarifiers, and membrane bioreactors.

Sludge Receiving and Aeration

The DRYPAC system receives WAS via either an existing pump or a Cloacina-supplied, pump. The sludge undergoes periodic aeration from a semi-sound-attenuated blower with medium bubble diffusers, which helps prevent sludge stagnation and mitigates odors. This aeration process minimizes manual intervention, ensuring consistent sludge quality and odor control.

Dewatering Process

For dewatering, operators initiate the system manually to configure appropriate settings, after which it functions with automated safeguards to prevent operational issues, including shutdowns for low sludge levels or equipment malfunctions. Pressate from the dewatering process is directed back to the plant’s headworks or to an established disposal area, while dewatered solids are deposited into a client-provided container, such as a dumpster, roll-off, or custom bin.

Integrated Equipment and Control

The DRYPAC package includes all necessary chemical and polymer dosing equipment, integrated into a central control system with remote access capabilities, allowing for monitoring and adjustments from any location. Equipment is arranged for optimal access, supporting ease of operation and maintenance.

Typical Applications

Any producer of liquid sludge desiring to reduce disposal costs through on-site dewatering

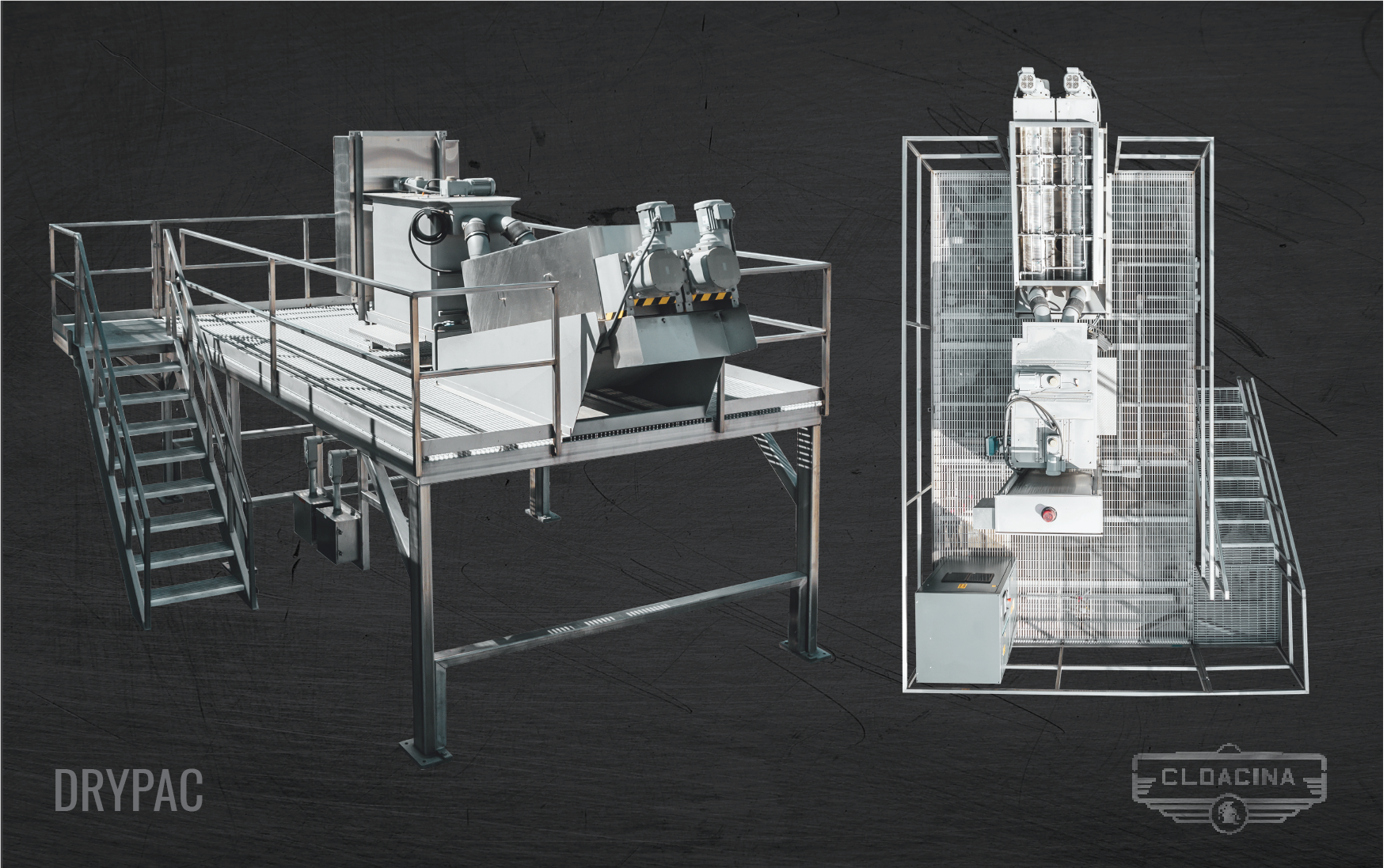

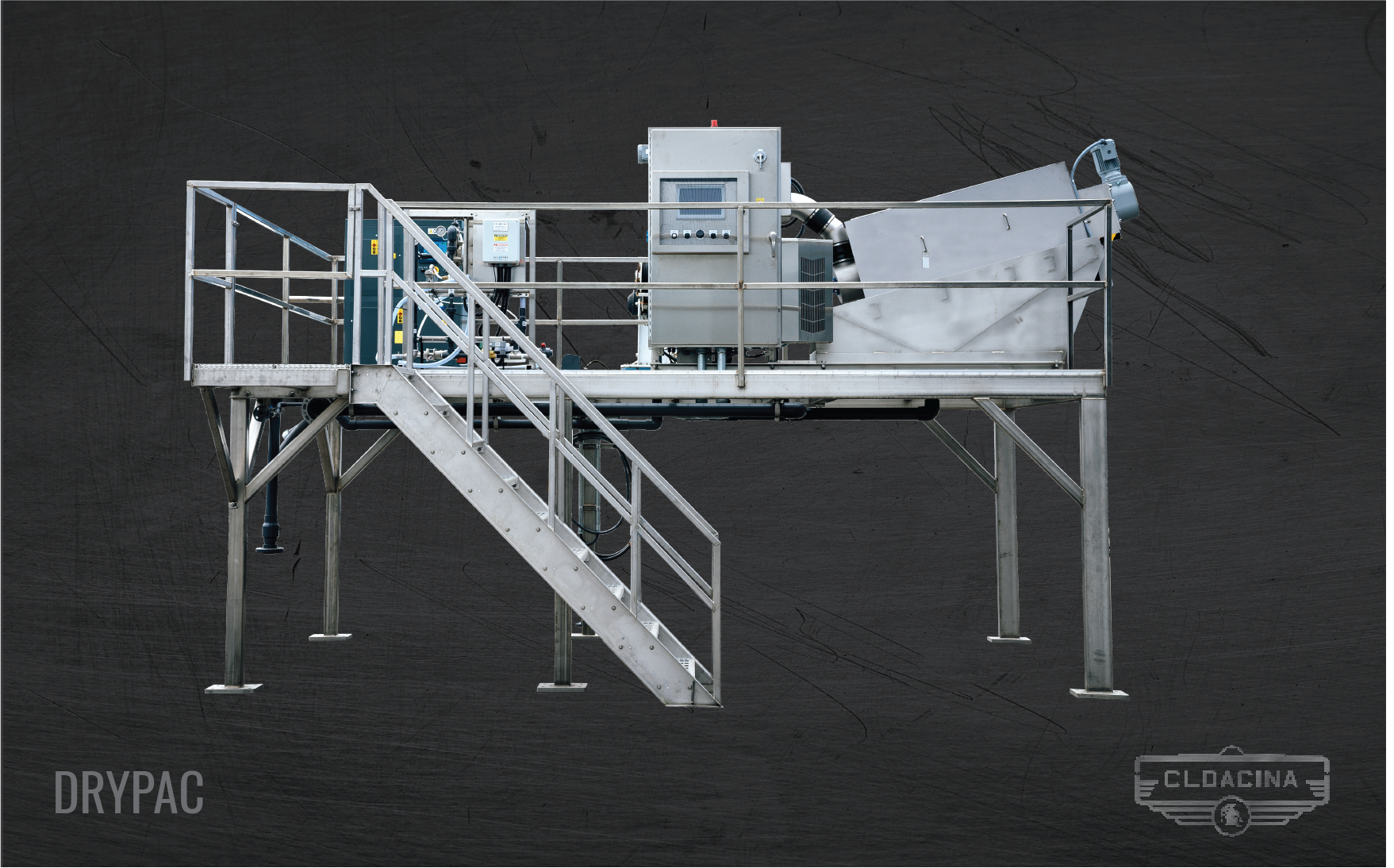

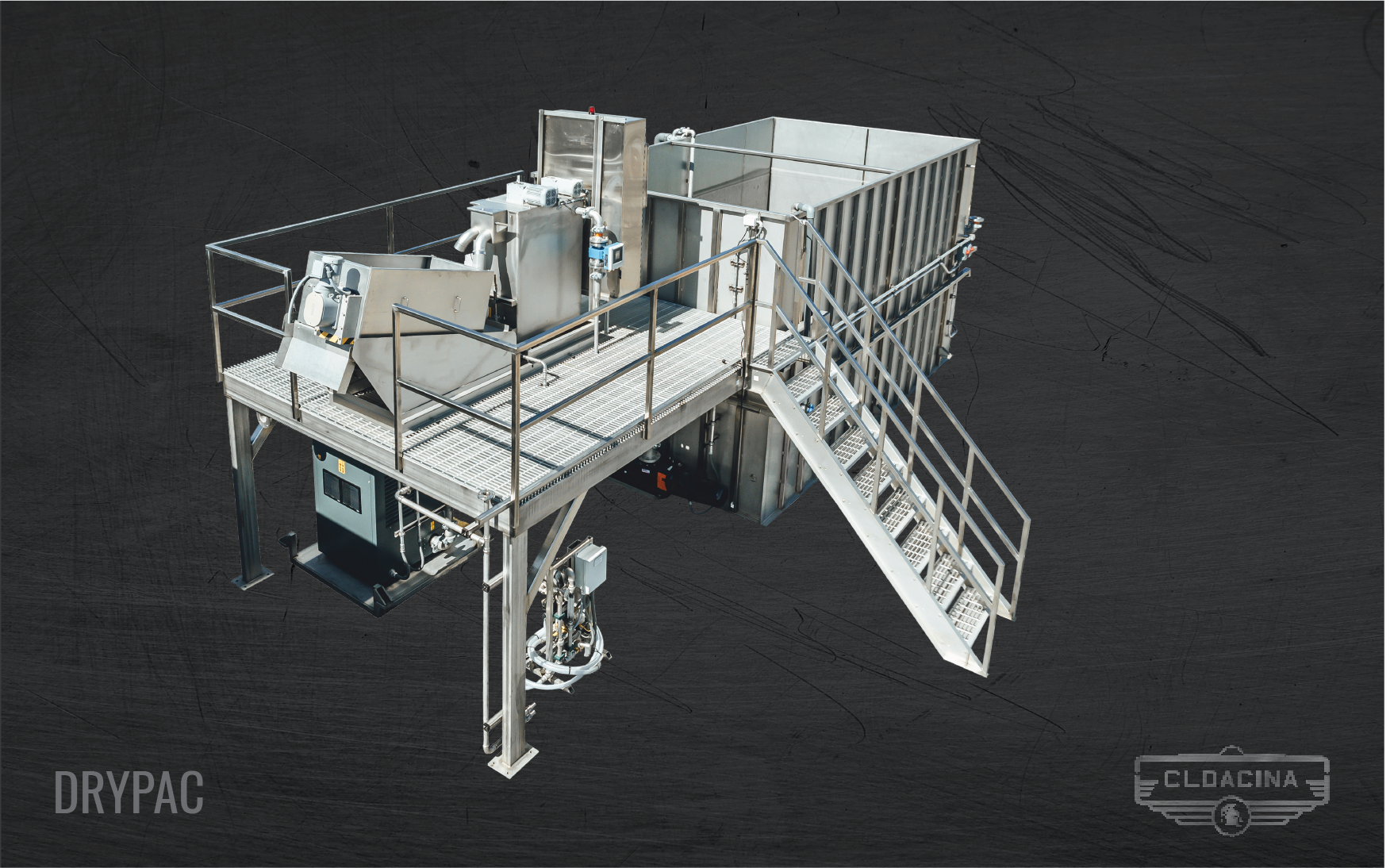

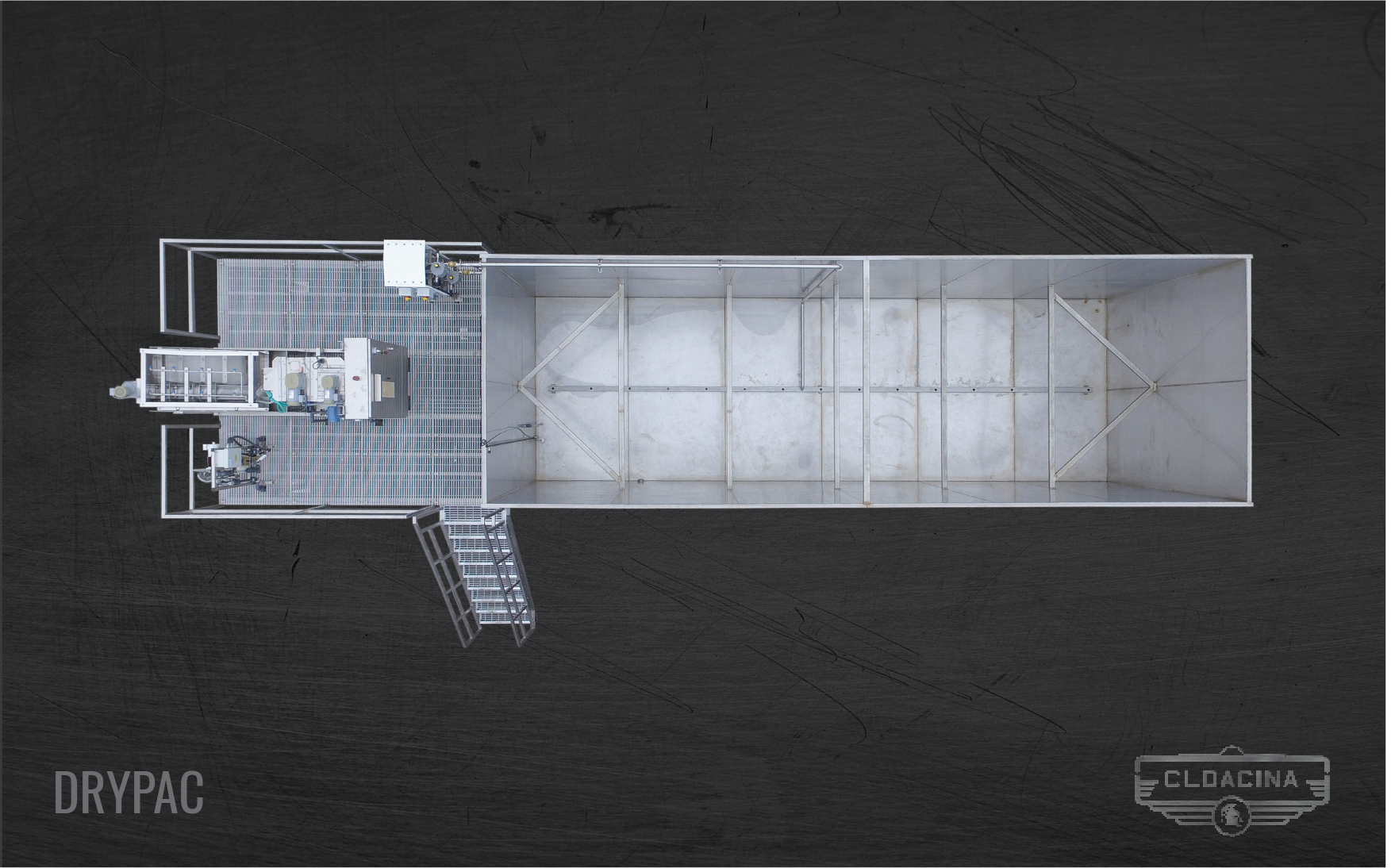

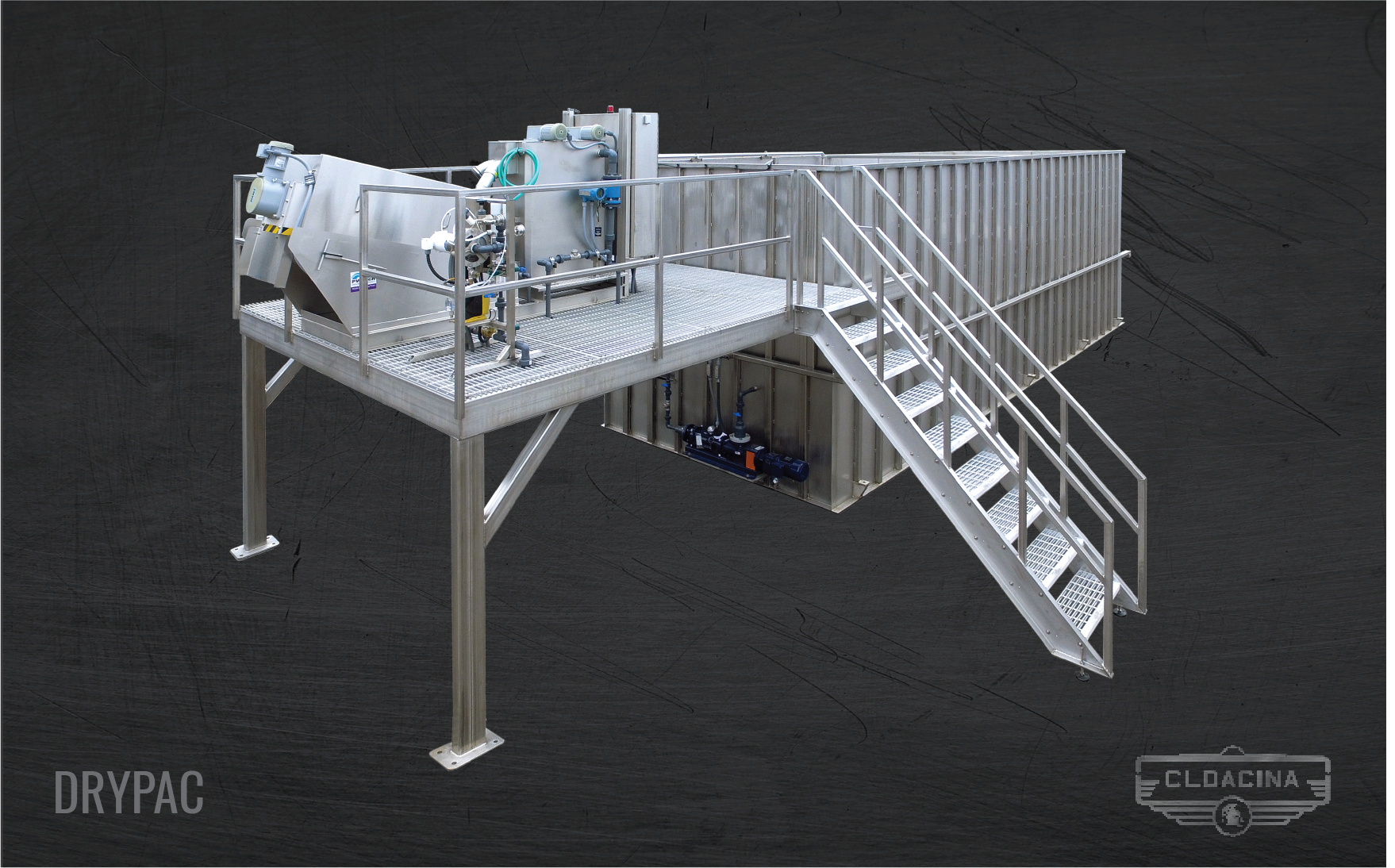

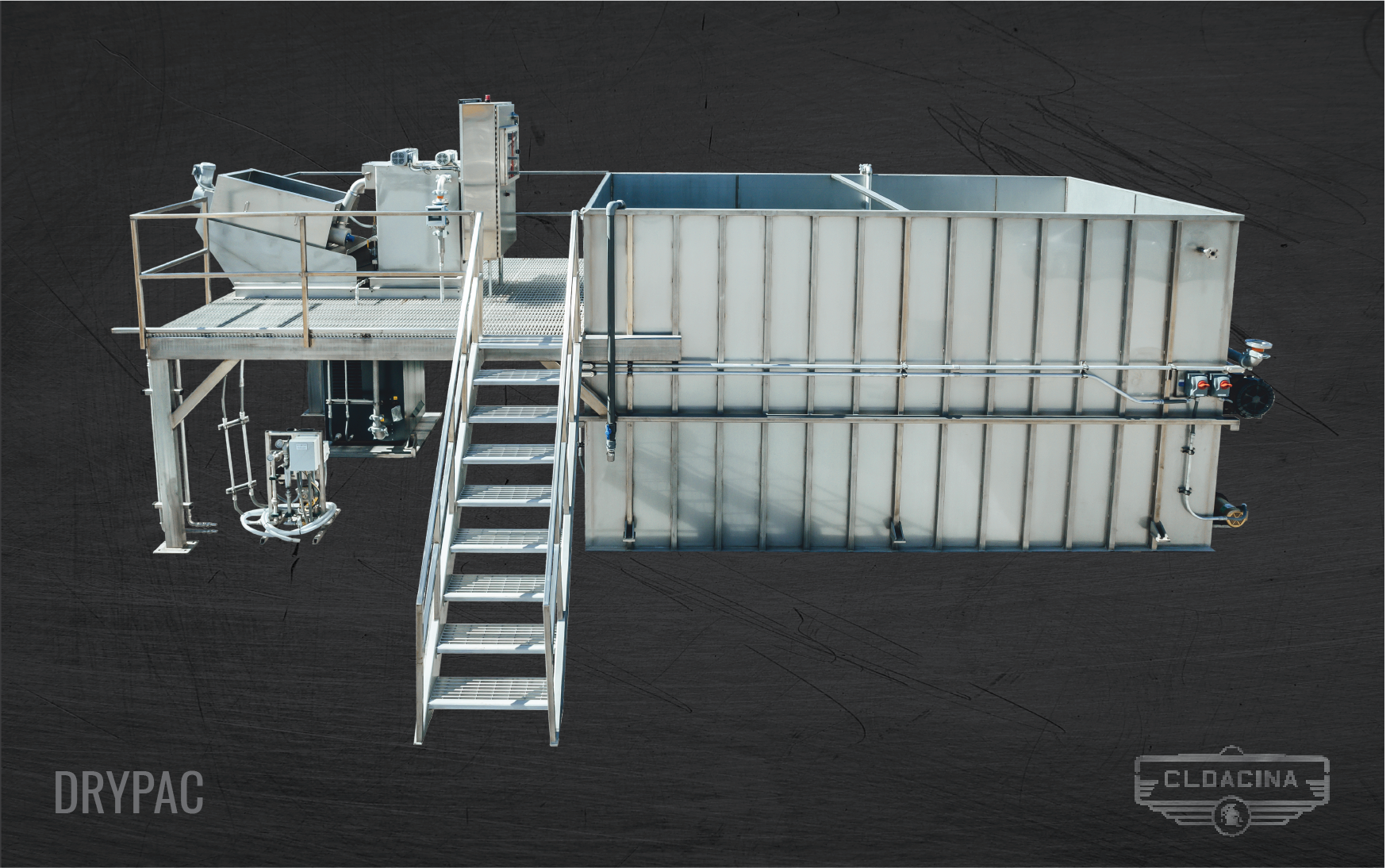

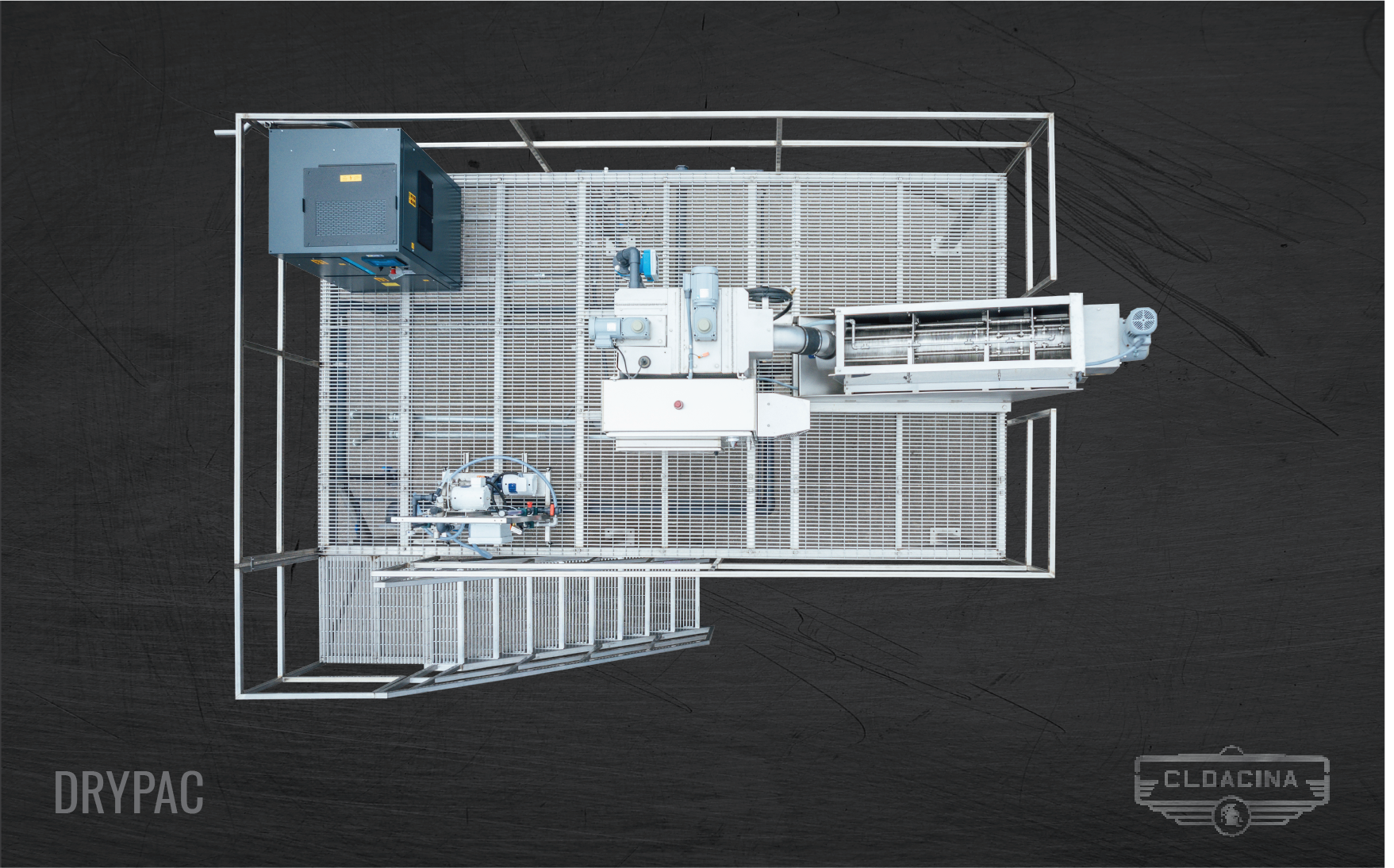

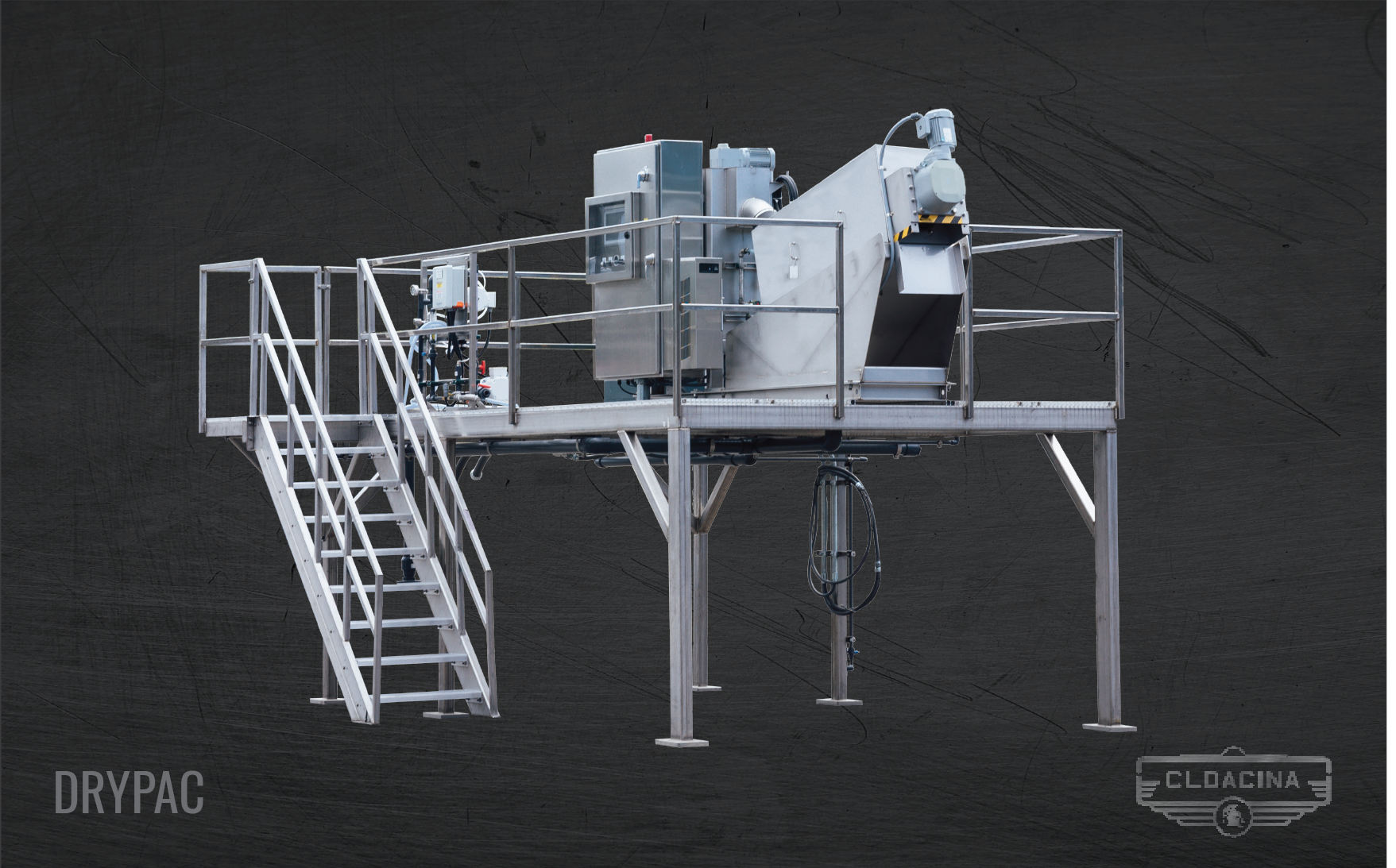

Product Photos

Aerated Storage and Transfer Pump

Dewatering Equipment

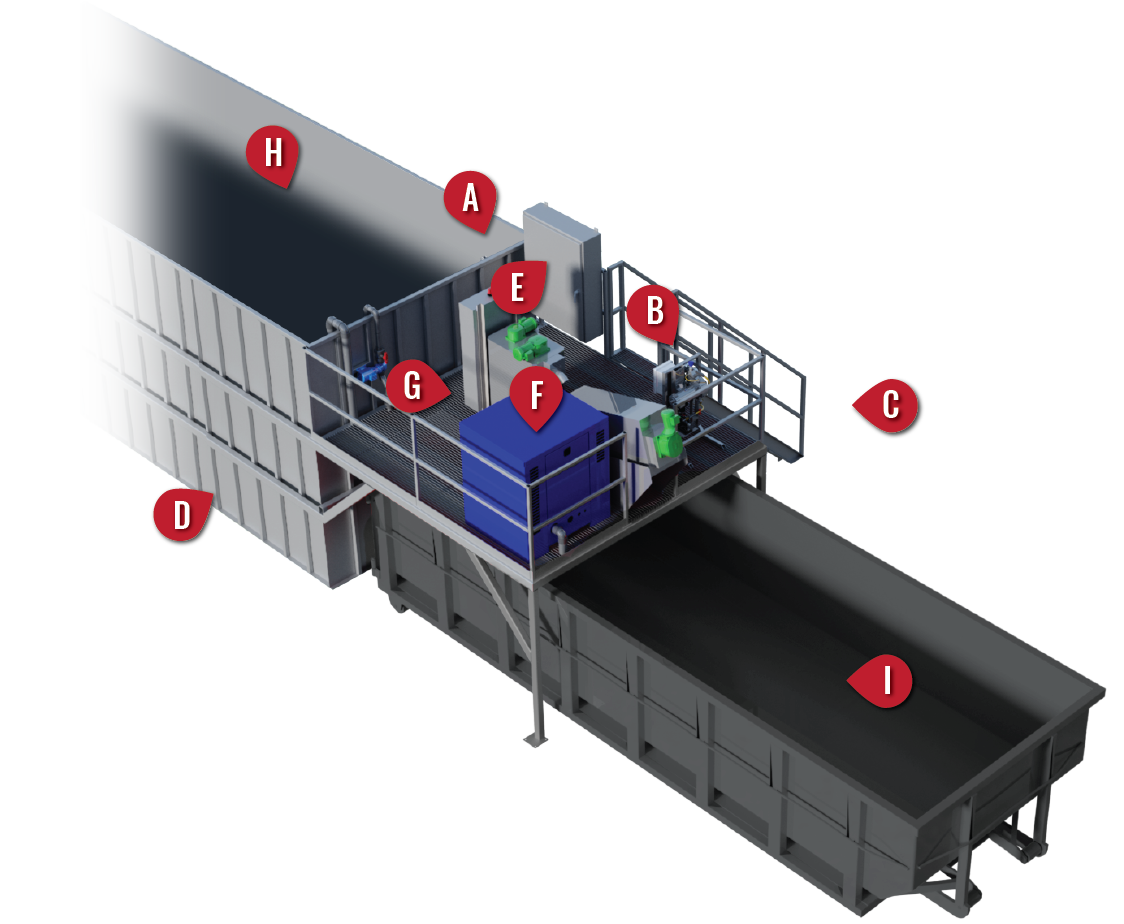

| A: | All sensory equipment is mounted on the Cloacina Slide Rail System and is accessible from the inspection platform |

| B: | Integrated polymer handling system |

| C: | Aluminum stairs and elevated platform(s) |

| D: | Corrosion-resistant 304 stainless steel tankage and components come standard |

| E: | Electrical panel and controls system are factory-installed and tested prior to shipping |

| F: | Semi-sound attenuated blowers |

| G: | All equipment is factory-installed and undergoes rigorous Factory Acceptance Testing (FAT) prior to shipping |

| H: | Aerated sludge holding tank |

| I: | Roll off bin – supplied by client |

STANDARD FEATURES

Tankage and skids are manufactured from 304 stainless steel

All equipment has been factory-tested prior to shipping

Unit typically ships in one piece and is ready to install

Startup services and training

OPTIONAL FEATURES

Extended equipment warranty

Automated dumpster wench

Odor control

Remote monitoring and alarm conditions of the DRYPAC system