The high Biochemical Oxygen Demand (BOD) and fluctuating flows associated with food, wine and other beverage process waste make them challenging to treat. Facility managers and compliance officers often struggle to meet discharge requirements, the violation of which can lead to staggering fines by regulatory agencies.

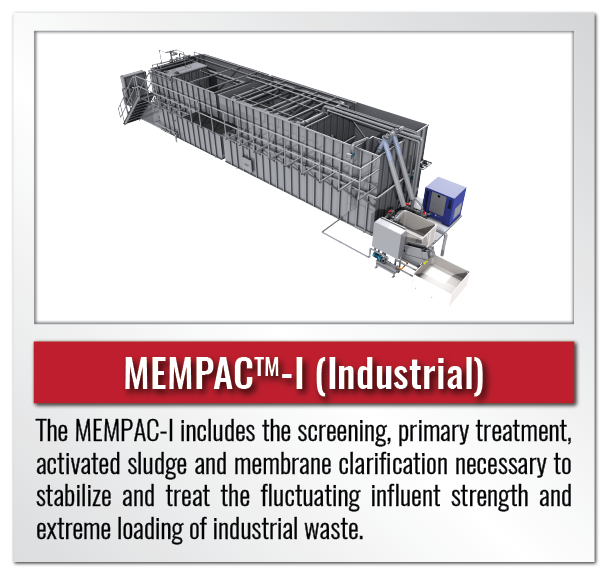

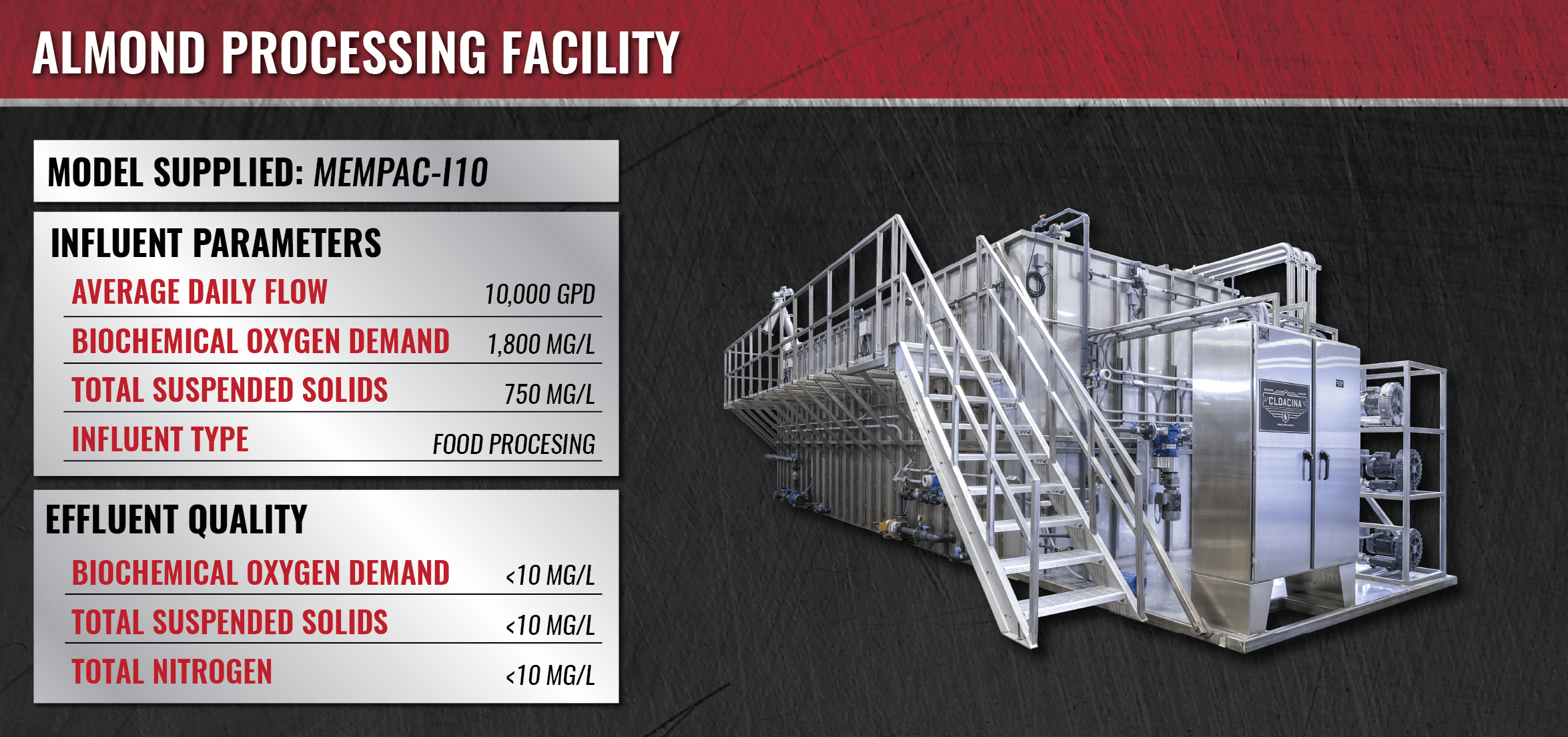

Cloacina’s MEMPAC-I, designed for high loading, is manufactured from stainless steel to combat the corrosive elements found in process waste. An automatic pH adjustment system with nutrient addition can be supplied to neutralize the waste stream. The multi-stage treatment process includes membrane clarification that reduces high BOD to within permit limits and prevents the discharge of solids into the sanitary sewer to meet discharge limitations. Solids management equipment decreases the volume of liquid waste hauled from the site. Flow can be monitored and sampled from multiple ports for reporting purposes. The advanced controls system automatically adjusts to production cycles, can be accessed by facility staff from any device with an Internet connection, alerts them when required maintenance is due and then logs tasks when completed. These features help food and beverage manufacturers meet their discharge requirements and maintain compliance with regulatory agencies.

• Facility evaluations

• Process evaluations and modeling

• Package wastewater treatment plant design, manufacturing, installation and operation

• Custom systems designed for the client’s specific waste stream and project phasing requirements

• Stand alone screening and headworks

• pH adjustment systems

• Lift stations

• Primary treatment prior to on-site treatment or sanitary sewer discharge

• Systems that can reclaim 100% of the treated effluent for irrigation or sanitation purposes

CLOACINA: INDUSTRY INNOVATORS

See why numerous engineers, project managers and winemakers choose Cloacina over other systems.

CLIENT INTERVIEW

Vera Rangel - Project Engineer

County of Los Angeles Internal Services Department

CLIENT INTERVIEW

Joe Hurliman - Winemaker

Herzog Wine Cellars