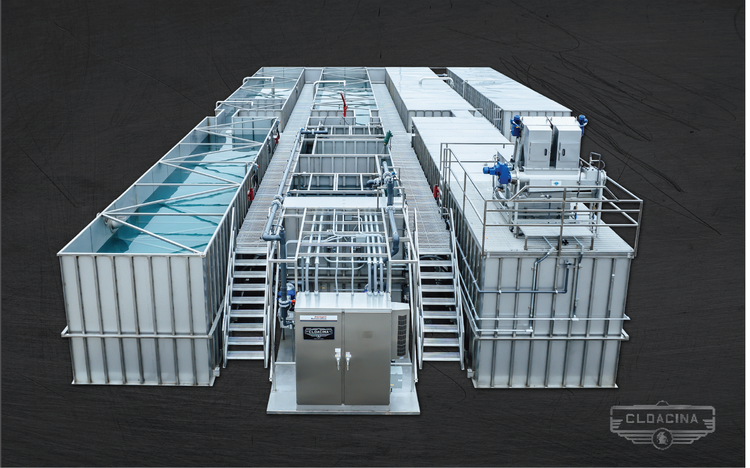

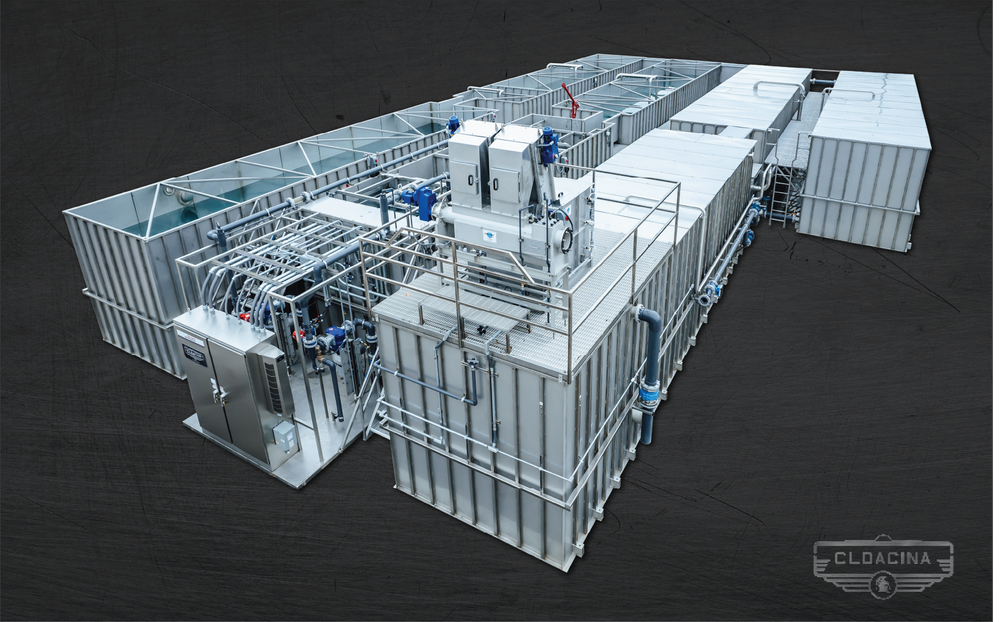

ABOUT THE MEMPAC-M

The MEMPAC-M is a high-performance wastewater treatment system designed for domestic applications. It uses advanced membrane bioreactor (MBR) technology to deliver high-quality effluent while minimizing space and operational complexity. All systems are assembled and wet-tested in-house before shipping, ensuring performance and quality control. MEMPAC-M meets even the most demanding discharge requirements and can reclaim 100% of treated effluent for reuse.

All MEMPAC-M models share the same quality standards, modular design principles, and high-performance features and are engineered for phased capacity expansion, allowing the system to grow alongside your project.

At Cloacina, we’re committed to being a trusted long-term partner — delivering dependable systems backed by real-world results and ongoing support.

PROVEN PRE-ENGINEERING

Each MEMPAC-M system is based on an extensively refined and field-informed design. Unlike traditional cast-in-place systems, which are often custom-built from scratch and prone to site-specific issues, the MEMPAC-M benefits from multiple generations of testing, equipment trials, and layout optimization. This pre-engineered approach reduces risk, shortens timelines, and ensures consistent performance across a wide range of operating conditions.

STANDARD FEATURES

These are the core components and systems included with every MEMPAC-M model.

- Intuitive and advanced controls system

- Human Machine Interface (HMI)

- All submersible mixers on slide rails

- Fine bubble aeration diffusers

- Low maintenance regenerative blowers

- Open-top flow channels between tanks with stop gates for isolation

- Independent membrane trains allow for maintenance or cleaning to be done without affecting capacity

- Automated Clean In Place (CIP) system

- Electrical panel and controls are factory installed on integrated equipment skid

- Corrosion-resistant 304 stainless steel tankage and components

- Aluminum stairs and platform(s)

- Catwalk supplied along the length of the system

- All process analytical sensors are mounted on the Cloacina Slide Rail System and accessible from the catwalk

- Davit crane and individual receivers for all submerged equipment

- Local disconnects and junction boxes for all motorized equipment

- Redundant membrane equipment

- Automated foam control

- Effluent flow metering

- Remote monitoring and support

- Factory tested prior to shipping

- Basic operations and maintenance training services

OPTIONAL FEATURES

Optional features are enhancements or upgrades that can be added to the base MEMPAC-M system to meet specific operational needs and are not factored into the base cost shown.

- Upgrade of stop gate to a weir gate for isolation

- Low-flow configuration and equipment

- Advanced treatment to meet lower nutrient limits

- Positive displacement blowers

- Sound-attenuated blowers

- Thermal protection

- Equipment awnings

- Extended warranty

OPTIONAL EQUIPMENT/SERVICES

Optional equipment refers to standalone products that can be seamlessly integrated with the MEMPAC-M system. Clients can select optional equipment based on site-specific needs and are not factored into the base cost shown.

- Effluent disposal pump station

- Centralized or integrated influent screening

- Sludge disposal equipment

- UV disinfection equipment

- Installation support

- Equalization storage and equipment

- Sediment and grit traps

- Package lift station

- Odor control equipment

- Operations and maintenance training video and portal support