On June 7, 2019 we opened our doors to the public for our third annual Open House. We had more than a hundred regulators, engineers, clients, vendors and members of the public tour our facility. In case you missed the tour, check out our latest video which shows all of the Cloacina plants and equipment that were on display that day.

Happy Independence Day!

Happy Independence Day from the Cloacina Family to yours!

Introducing Cloacina Pacific!

We are proud to announce the launch of Cloacina Pacific – a new product line designed specifically to address the challenges associated with island wastewater treatment and overseas shipping! All five MEMPAC membrane bioreactor models are the size of a sea train cargo container and can reclaim 100% of the treated effluent for irrigation and sanitation purposes. Cloacina also has a product representative based in Hawaii that can assist Pacific Island clients with budgetary estimates, process questions and on-going support after installation. Cloacina is the only Pacific manufacturer of package wastewater treatment plants and industry equipment.

Coming soon to a botanical garden near you!

Cloacina is proud to announce that we were selected to build a 40,000 gallon per day MEMPAC-M for the Descanso Gardens! Located in Los Angeles County, this botanical garden had more than a half a million visitors in 2017. The 150 acre property features a Japanese garden, extensive plant collections, the Boddy House Mansion, the Sturt Haaga Gallery, a railroad and restaurant. The MEMPAC-M will reclaim 100% of the treated effluent for irrigation purposes.

Case Study Concannon

Cloacina provided a 24,000 Gallon Per Day (GPD) MEMPAC-I and all appurtenant equipment for the Concannon bottling facility located in Livermore, California. The package plant was designed, fabricated and installed in less than 30 days. Cloacina and Fluid Resource Management provided complete design/build services and assisted the Client with city and county permitting. The MEMPAC-I reclaims 100% of the treated effluent which Concannon uses for vineyard irrigation. There is a city sewer connection but it has never been utilized.

View the full case study here: https://www.cloacina.com/concannon

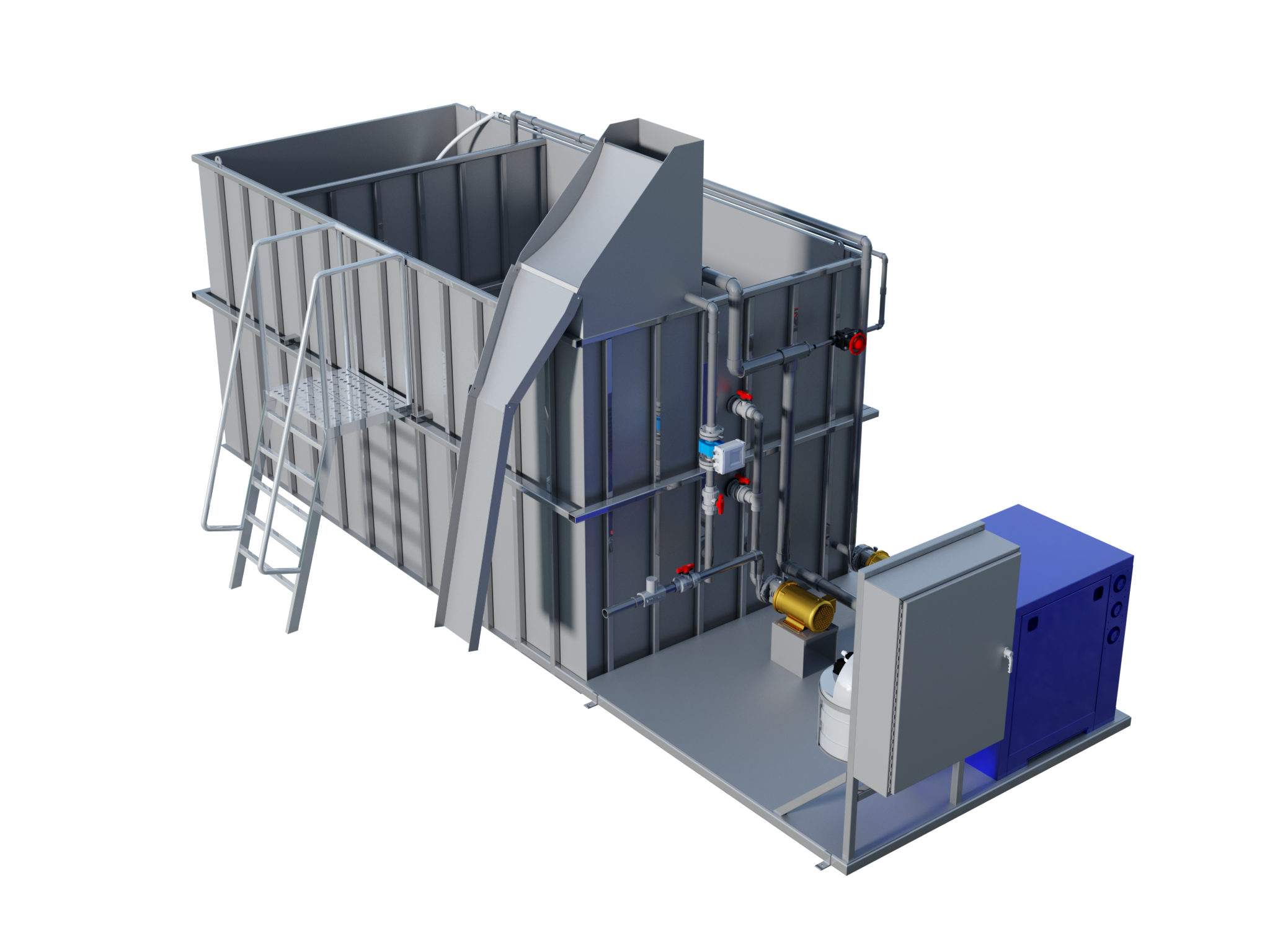

Featured Product: IBR

Cloacina’s Industrial Batch Reactor™ (IBR) is a package wastewater treatment plant that treats industrial wastewater utilizing activated sludge and clarification in a single vessel. All interior and exterior components are manufactured from high-quality, corrosion-resistant materials. The tank and equipment skid are fabricated from stainless steel. Cloacina’s IBR is ideal for clients needing a wastewater system with a small footprint that can pre-treat wastewater prior to sewer disposal, sub-surface reuse and frost and/or dust control water. The system includes a cutting-edge control system which allows facility staff to remotely access, monitor and make changes to the plant, collect data for reporting, view live on-site video and verify the completion of routine maintenance. The IBR is factory-tested, completely assembled prior to shipment and is easy to install, operate and maintain. Models are available for buried, partially-buried and above-grade installations. The Industrial Batch Reactor can be installed in compact and remote locations. Learn more here: https://www.cloacina.com/industrial-batch-reactor-ibr

MEMPAC-E for the Gold Creek Center in Sylmar, CA

Currently on the factory floor and under construction is a 10,000 gallon per day MEMPAC-E for the Gold Creek Center in Sylmar, CA. The MEMPAC-E is Cloacina's economy membrane bioreactor. Learn more here: https://www.cloacina.com/economy-membrane-bio-reactor

What to Expect in 2019

2019 is shaping up to be another historic year for Cloacina. See what to expect as the new year unfolds.